HYTORC Nut

Fasteners

Industrial Bolting Systems

For critical applications requiring the highest level of bolt load control, the patented HYTORC Nut system provides industry-leading joint integrity. This three-piece fastener applies pure tension to the bolt to prevent thread damage and ensure bolt load accuracy. Available in a variety of materials to suit all applications, from extreme temperatures to harsh climates.

Bolt Tensioner - Calibrated Load Accuracy

No other bolting system provides the same level of repeatable accuracy, ensuring even bolt load to eliminate joint failure and unintentional nut loosening.Tool Longevity

Other bolting systems put the reaction arm and square drive on opposite sides of the tool causing high stress in the body of the tool, which can lead to failure over time. The HYTORC Nut puts the action and reaction on the square drive axis to eliminate the majority of internal stress, and increase the lifetime of your tools.Gall-free Removal

The HYTORC Nut is the only fastener that can guarantee the elimination of galled or damaged threads on installation and removal. These fasteners have been installed on various high temperature applications for ten years and longer, and were removed without damage to the bolts, providing tremendous savings by eliminating the need for bolt replacement.Documentation

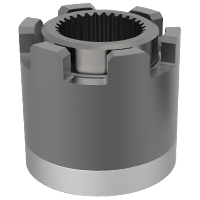

TN SERIES

TN SERIES GT SERIES

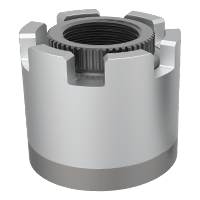

GT SERIES CT SERIES

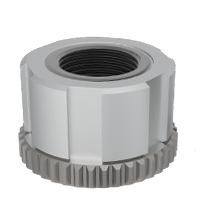

CT SERIES SN SERIES

SN SERIESTURBINE STYLE LIMITED RADIUS NUT

Our most popular Nut! Designed to overcome the tight radial restrictions and high temperatures in steam turbine engines. When a bolted connection has a challenging counter bore or flanged radius, the TN-Series Nut will solve the problem.CHEMICAL STYLE LIMITED RADIUS NUT

The CT Nut’s thicker outer sleeve minimizes stress and allows it to handle high loads at elevated temperatures. The through-bolt design makes them ideal for applications with high stud protrusions from the flange.LOW CLEARENCE STYLE NUT

The low-profile SN Series is the ideal choice for tight overhead restrictions where traditional fasteners can’t fit. The through-bolt design is useful for situations where high stud extensions make standard nuts impractical.GAS TURBINE STYLE NUT

Originally specified for Gas Turbine applications to handle elevated temperatures, high stress and greater load to breakout factors. For oversized applications where higher loads and breakout torques are needed.Imperial

Metric

TN Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 7/8 | 1.400 | 1.313 | 0.197 |

| 02 | 100 | 1 | 1.600 | 1.500 | 0.225 |

| 03 | 102 | 1-1/8 | 1.800 | 1.688 | 0.254 |

| 04 | 104 | 1-1/4 | 2.000 | 1.875 | 0.281 |

| 05 | 106 | 1-3/8 | 2.200 | 2.063 | 0.310 |

| 06 | 108 | 1-1/2 | 2.400 | 2.250 | 0.338 |

| 07 | 110 | 1-5/8 | 2.600 | 2.438 | 0.366 |

| 08 | 112 | 1-3/4 | 2.800 | 2.625 | 0.394 |

| 09 | 114 | 1-7/8 | 3.000 | 2.813 | 0.422 |

| 10 | 200 | 2 | 3.200 | 3.000 | 0.450 |

| 11 | 204 | 2-1/4 | 3.600 | 3.375 | 0.506 |

| 12 | 208 | 2-1/2 | 4.000 | 3.750 | 0.563 |

| 13 | 212 | 2-3/4 | 4.400 | 4.125 | 0.619 |

| 14 | - | - | 4.535 | 4.253 | 0.638 |

| 15 | 300 | 3 | 4.800 | 4.500 | 0.675 |

| 16 | - | - | 5.040 | 7.725 | 0.709 |

| 17 | 304 | 3-14 | 5.200 | 4.875 | 0.731 |

| 18 | 308 | 3-1/2 | 5.600 | 5.250 | 0.788 |

| 19 | 312 | 3-3/4 | 6.000 | 5.625 | 0.844 |

| 20 | 400 | 4 | 6.400 | 6.000 | 0.900 |

| 21 | 404 | 4-1/4 | 6.800 | 6.375 | 0.956 |

| 22 | 408 | 4-1/2 | 7.200 | 6.750 | 1.013 |

| 23 | 412 | 4-3/4 | 7.600 | 7.125 | 1.069 |

| 24 | 500 | 5 | 8.000 | 7.500 | 1.125 |

| 25 | 504 | 5-1/4 | 8.400 | 7.875 | 1.181 |

| 26 | 508 | 5-1/2 | 8.800 | 8.250 | 1.238 |

TN Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 022 | M20 | 35.56 | 33.35 | 5.00 |

| 02 | 024 | M24 | 40.64 | 38.10 | 5.72 |

| 03 | 027 | M27 | 45.72 | 42.88 | 6.45 |

| 04 | 030 | M30 | 50.80 | 47.63 | 7.14 |

| 05 | 033 | M33 | 55.88 | 52.40 | 7.87 |

| 06 | 036 | M36/M39 | 60.96 | 60.96 | 8.59 |

| 07 | 039 | M42* | 66.04 | 61.93 | 9.30 |

| 08 | 042 | M45 | 71.12 | 66.68 | 10.01 |

| 09 | 045 | M48 | 76.20 | 71.45 | 10.72 |

| 10 | 048 | M52 | 81.28 | 76.20 | 11.43 |

| 11 | 052 | M56 | 91.44 | 85.73 | 12.85 |

| 12 | 056 | M64 | 101.60 | 95.25 | 14.30 |

| 13 | 064 | M70 | 111.76 | 104.78 | 15.72 |

| 14 | 070 | M72 | 115.19 | 108.03 | 16.21 |

| 15 | 072 | M76 | 121.92 | 114.30 | 18.01 |

| 16 | 076 | M80 | 128.02 | 120.02 | 18.01 |

| 17 | 080 | - | 132.08 | 123.83 | 18.57 |

| 18 | - | M90 | 142.24 | 133.35 | 20.02 |

| 19 | 090 | M95 | 152.40 | 142.88 | 21.44 |

| 20 | 095 | M100 | 162.56 | 152.40 | 22.86 |

| 21 | 100 | M110 | 172.72 | 161.93 | 24.28 |

| 22 | 110 | M115 | 182.88 | 171.45 | 25.73 |

| 23 | 115 | M120 | 193.04 | 180.98 | 27.15 |

| 24 | 120 | M125 | 203.20 | 190.50 | 28.58 |

| 25 | 125 | M130 | 213.36 | 200.03 | 30.00 |

| 26 | 130 | M140 | 223.52 | 209.55 | 31.45 |

CT Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 7/8 | 1.660 | 1.429 | 0.201 |

| 02 | 100 | 1 | 1.811 | 1.559 | 0.220 |

| 03 | 102 | 1-1/8 | 2.038 | 1.754 | 0.247 |

| 04 | 104 | 1-1/4 | 2.264 | 1.949 | 0.275 |

| 05 | 106 | 1-3/8 | 2.491 | 2.144 | 0.302 |

| 06 | - | - | 2.717 | 2.339 | 0.330 |

| 07 | 108 | 1-1/2 | 2.943 | 2.533 | 0.357 |

| 08 | 110 | 1-5/8 | 3.170 | 2.728 | 0.384 |

| 09 | 112 | 1-3/4 | 3.396 | 2.923 | 0.412 |

| 10 | 114 | 1-7/8 | 3.623 | 3.118 | 0.439 |

| 11 | 200 | 2 | 3.925 | 3.378 | 0.476 |

| 12 | 204 | 2-1/4 | 4.226 | 3.638 | 0.513 |

| 13 | 208 | 2-1/2 | 4.830 | 3.914 | 0.586 |

| 14 | 212 | 2-3/4 | 5.283 | 4.547 | 0.614 |

| 15 | - | - | 5.434 | 4.677 | 0.659 |

| 16 | 300 | 3 | 5.736 | 4.937 | 0.696 |

| 17 | - | - | 6.038 | 5.197 | 0.732 |

| 18 | 304 | 3-1/4 | 6.340 | 5.457 | 0.769 |

| 19 | 308 | 3-1/2 | 6.793 | 5.846 | 0.824 |

CT Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 022 | M22 | 42.16 | 36.30 | 5.11 |

| 02 | 024 | M24 | 46.00 | 39.30 | 5.59 |

| 03 | 027 | M27 | 51.77 | 44.55 | 6.27 |

| 04 | 030 | M30 | 57.51 | 49.50 | 6.99 |

| 05 | 033 | M33 | 63.27 | 54.46 | 7.67 |

| 06 | 036 | M36 | 69.01 | 59.41 | 8.38 |

| 07 | 039 | M39 | 74.75 | 64.34 | 9.07 |

| 08 | 042 | M42 | 80.52 | 69.29 | 9.75 |

| 09 | 045 | M45 | 86.26 | 74.24 | 10.46 |

| 10 | 048 | M48 | 92.02 | 79.20 | 11.15 |

| 11 | 052 | M52 | 99.70 | 85.80 | 12.09 |

| 12 | 056 | M56 | 107.34 | 92.41 | 13.03 |

| 13 | 064 | M64 | 122.68 | 99.42 | 14.88 |

| 14 | 070 | M70 | 134.19 | 115.49 | 15.60 |

| 15 | 072 | M72 | 138.02 | 118.80 | 16.74 |

| 16 | 076 | M76 | 145.69 | 125.40 | 17.68 |

| 17 | 080 | M80 | 153.37 | 132.00 | 18.59 |

| 18 | - | - | 161.04 | 138.61 | 19.53 |

| 19 | 090 | M90 | 172.54 | 148.49 | 20.93 |

SN Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 5/8-7/8 | 1.880 | 1.210 | - |

| 02 | 100 | 1 | 2.050 | 1.210 | 0.225 |

| 03 | 102 | 1-1/8 | 2.313 | 1.360 | 0.249 |

| 04 | 104 | 1-1/4 | 2.500 | 1.518 | 0.281 |

| 05 | 106 | 1-3/8 | 2.688 | 1.670 | 0.310 |

| 06 | 108 | 1-1/2 | 2.938 | 1.821 | 0.338 |

| 07 | 110 | 1-5/8 | 3.250 | 1.974 | 0.366 |

| 08 | 112 | 1-3/4 | 3.417 | 2.125 | 0.394 |

| 09 | 114 | 1-7/8 | 3.667 | 2.277 | 0.422 |

| 10 | 200 | 2 | 3.900 | 2.429 | 0.450 |

| 11 | 204 | 2-1/4 | 4.300 | 2.732 | 0.506 |

| 12 | 208 | 2-1/2 | 4.800 | 3.035 | 0.563 |

| 13 | 212 | 2-3/4 | 5.250 | 3.338 | 0.619 |

| 14 | - | 2-7/8 | 5.375 | 3.440 | 0.638 |

| 15 | 300 | 3 | 5.750 | 3.643 | 0.675 |

| 16 | - | - | 5.750 | 3.824 | 0.709 |

| 17 | 304 | 3-1/4 | 6.083 | 3.945 | 0.731 |

| 18 | 308 | 3-1/2 | 6.667 | 4.250 | 0.788 |

| 19 | 312 | 3-3/4 | 7.000 | 4.550 | 0.844 |

| 20 | 400 | 4 | 7.300 | 4.857 | 0.900 |

| 21 | 404 | 4-1/4 | 7.750 | 5.159 | 0.956 |

| 22 | 408 | 4-1/2 | 8.200 | 5.463 | 1.013 |

| 23 | 412 | 4-3/4 | 8.700 | 5.930 | 1.069 |

SN Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | M20 | 52.07 | 30.73 | - |

| 02 | 024 | M24 | 52.07 | 30.73 | 5.71 |

| 03 | 027 | M27 | 58.67 | 34.54 | 6.47 |

| 04 | 030 | M30 | 63.50 | 38.56 | 7.23 |

| 05 | 033 | M33 | 68.33 | 42.42 | 7.81 |

| 06 | 036 | M36/39 | 74.68 | 46.25 | 8.57 |

| 07 | 042 | M42 | 82.55 | 50.14 | 9.33 |

| 08 | 045 | M45 | 86.87 | 53.98 | 10.09 |

| 09 | 048 | M48 | 93.22 | 57.91 | 10.66 |

| 10 | 052 | M52 | 99.06 | 61.72 | 11.43 |

| 11 | 056 | M56 | 109.22 | 69.34 | 12.95 |

| 12 | 064 | M64 | 121.92 | 77.22 | 14.28 |

| 13 | 070 | M70 | 133.35 | 84.84 | 15.81 |

| 14 | 072 | M72 | 136.65 | 87.38 | 16.19 |

| 15 | 076 | M76 | 146.05 | 92.53 | 17.14 |

| 16 | 080 | M80 | 146.05 | 97.03 | 18.09 |

| 17 | - | - | 154.43 | 100.33 | 18.66 |

| 18 | 090 | M90 | 169.42 | 107.95 | 20.95 |

| 19 | 095 | M95 | 177.80 | 115.57 | 21.52 |

| 20 | 100 | M100 | 185.42 | 123.44 | 22.86 |

| 21 | 110 | M110 | 196.85 | 131.06 | 24.38 |

| 22 | 115 | M115 | 208.28 | 138.76 | 25.71 |

| 23 | 120 | M120 | 220.98 | 150.62 | 27.24 |

GT Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 02 | 100 | 1 | 1.850 | 1.648 | 0.205 |

| 03 | 102 | 1-1/8 | 2.081 | 1.823 | 0.263 |

| 04 | 104 | 1-1/4 | 2.313 | 2.146 | 0.281 |

| 05 | 106 | 1-3/8 | 2.544 | 2.334 | 0.338 |

| 06 | 108 | 1-1/2 | 2.775 | 2.487 | 0.338 |

| 07 | 110 | 1-5/8 | 3.006 | 2.656 | 0.352 |

| 08 | 112 | 1-3/4 | 3.238 | 2.750 | 0.394 |

| 09 | 114 | 1-7/8 | 3.469 | 3.094 | 0.422 |

| 10 | 200 | 2 | 3.700 | 3.145 | 0.450 |

| 11 | 204 | 2-1/4 | 4.163 | 3.540 | 0.506 |

| 12 | 208 | 2-1/2 | 4.625 | 4.073 | 0.574 |

| 13 | 212 | 2-3/4 | 5.088 | 4.349 | 0.680 |

| 14 | 214 | 2-7/8 | 5.244 | 4.477 | 0.698 |

| 15 | 300 | 3 | 5.550 | 4.787 | 0.675 |

GT Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 02 | 024 | M24 | 46.99 | 41.85 | 6.34 |

| 03 | 027 | M27 | 52.86 | 46.30 | 6.67 |

| 04 | 030 | M30 | 58.75 | 54.51 | 7.14 |

| 05 | 033 | M33 | 64.62 | 59.28 | 8.57 |

| 06 | 036 | M36/M39 | 70.49 | 63.17 | 8.57 |

| 07 | 042 | M42* | 76.35 | 67.46 | 8.93 |

| 08 | 045 | M45 | 82.25 | 69.85 | 10.00 |

| 09 | 048 | M48 | 88.11 | 78.59 | 10.72 |

| 10 | 052 | M52 | 93.98 | 79.88 | 11.43 |

| 11 | 056 | M56 | 105.74 | 89.92 | 12.85 |

| 12 | 064 | M64 | 117.48 | 103.45 | 14.57 |

| 13 | 070 | M70 | 129.24 | 110.46 | 17.26 |

| 14 | 072 | M72 | 133.20 | 113.72 | 17.74 |

| 15 | 076 | M76 | 140.97 | 121.59 | 17.15 |

English (South Africa)

English (South Africa)  Deutsch (Deutschland)

Deutsch (Deutschland)  简体中文(中国)

简体中文(中国)  Español (España)

Español (España)  English (Singapore)

English (Singapore)  Français (France)

Français (France)  English (Australia)

English (Australia)  English (United States)

English (United States)  English (United Kingdom)

English (United Kingdom)